The fourth revolution in industrial processes is currently underway, and it is being called Industry 4.0. Data, and the way data is collected, shared and analyzed, is at the core of this revolution. Are your machines ready to be apart of the “smart factory?”

Smart Sensors from SICK

Smart sensors are a prerequisite for effective implementation of Industry 4.0. SICK has been enabling their customers with smarter sensors for many years. Now, with the inclusion of industry-standard IO-Link communication technology, SICK’s sensors are smarter than they have ever been. SICK is leveraging IO-Link to enable:

- Enhanced Sensing

- Efficient Sensor Communication

- Sensor Diagnostics

- Smart Sensor Tasks

Enhanced Sensing

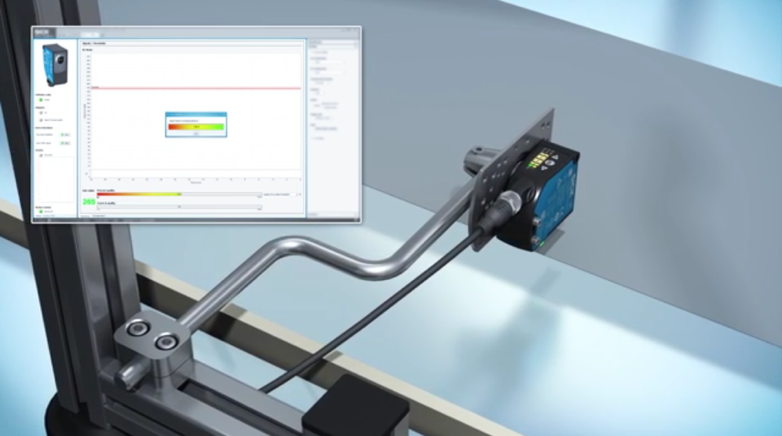

Have you ever struggled to correctly adjust or teach a sensor during installation and setup? SICK sensors with IO-Link can talk to SICK’s free SOPAS software, allowing you use your PC to “see” what the sensors sees. You don’t need an analog input to graph the sensor’s output, as SOPAS “talks” to the sensor to get the raw data and displays it in an easy-to-digest format. Now you can be sure that your sensor configuration is optimized to your process, offering increased detection reliability and machine uptime.

Since you can now “talk” to your sensor, you can also make adjustments on the fly without needing physical access to the device. In fact, because physical access it not necessary to make adjustments, you can now prevent tampering by selectively disabling control elements, such as buttons or potentiometers, on the sensor. You are now in control more than you have ever been.

Efficient Sensor Communication

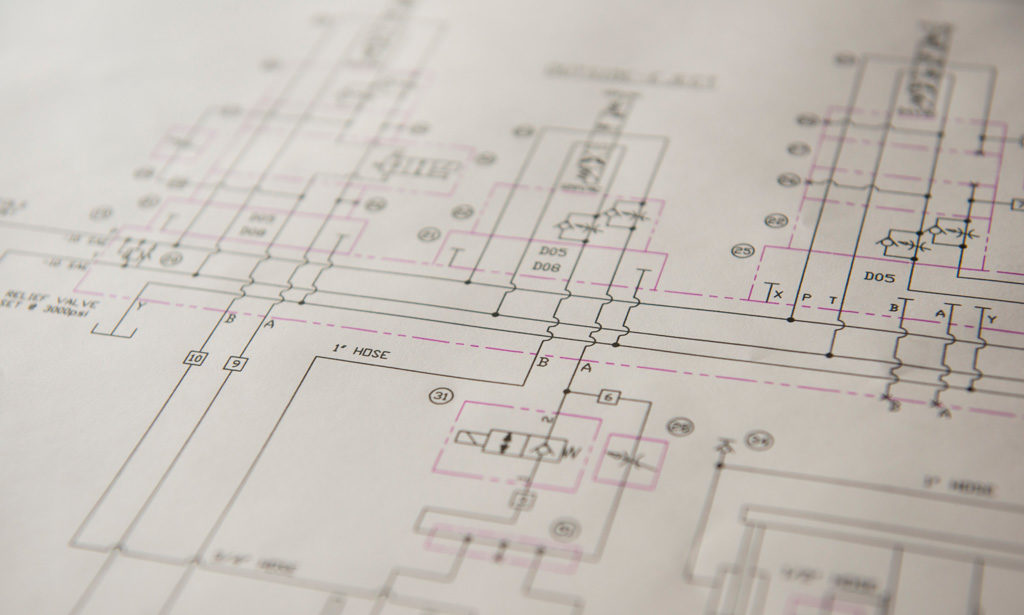

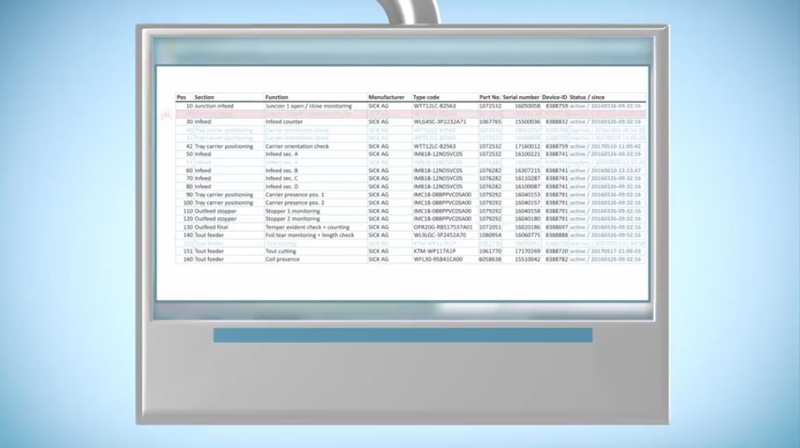

With Smart Sensors from SICK, your process information is now digitized right at the source. This means that traditional analog values (0-10 VDC, 4-20 mA) are now transmitted as 1’s and 0’s, making the information less susceptible to electrical noise. You can use standard, unshielded, sensor cables and be sure that the communication protocol will look after your data. Furthermore, you can now inventory all of the sensors on your machine, because each sensor can report its model number, serial number and even its current configuration. This means that you can create a parts list AND backups of your sensor configurations that can be automatically loaded into a new sensor upon replacement. Not only does this decrease downtime for unexpected maintenance, but it can also improve machine safety by preventing unapproved or invalid device configurations. Going one step further, all of this can be logged so that you know exactly what has been happening on your machine!

Sensor Diagnostics

What if your sensor could tell you when it was failing, before it failed? While it has been possible to log and trend machine data in a PLC for quite some time, doing this for every sensor on your machine was too costly, impractical, or even impossible. Smart Sensors from SICK can now do that monitoring for you, even alerting you when “something” has changed.

Often the most time consuming portion of troubleshooting a down machine is locating the error. Imagine a photoelectric sensor that tells you when it is dirty? Now that your sensor can tell you what is wrong you can fix the problems before they become a problem! With Smart Sensors from SICK you can rest assured that your machine is helping you watch your back.

Smart Sensor Tasks

With data being the center of Industry 4.0, how to you ensure that you are not overwhelmed with unnecessary data? SICK has enabled Smart Tasks inside their sensors to process and transmit only the relevant information that you need to make your machine operate efficiently. Smart Tasks will lighten the processing load in your machine controller, shorten the development and commissioning time and can eliminate cost in the form of specialty hardware for processing specific tasks such as object speed monitoring or length measurement.

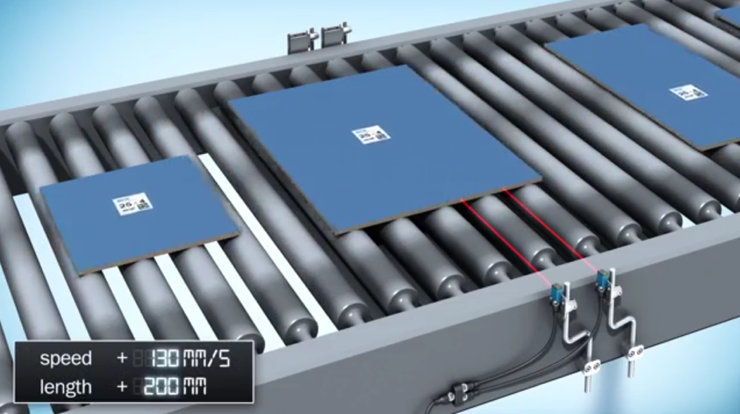

Using Smart Tasks, two sensors can locally share their information to act as a single sensor. Using IO-Link’s ability to configure advanced parameters, the distance between the two sensors can be used with the time between the two signals to measure length and speed of a part. Now you are measuring true object speed, without worry of slippage error common to rollers and belts! Other Smart Tasks enable you to configure signal debouncing, right in the sensor. Measure gaps between product to help you identify placement problems and more quickly sort good from bad parts. Smart Tasks from SICK help you enable your “smart factory” by allowing you to decentralize decision making and place it where it makes the most sense.

Call Tec-Hackett and ask for one of our SICK Specialists to talk more about!

Read more at www.sick.com

Email us at sickhelp@tec-hackett.com